Whitney Dancing Stand Development, Part 2

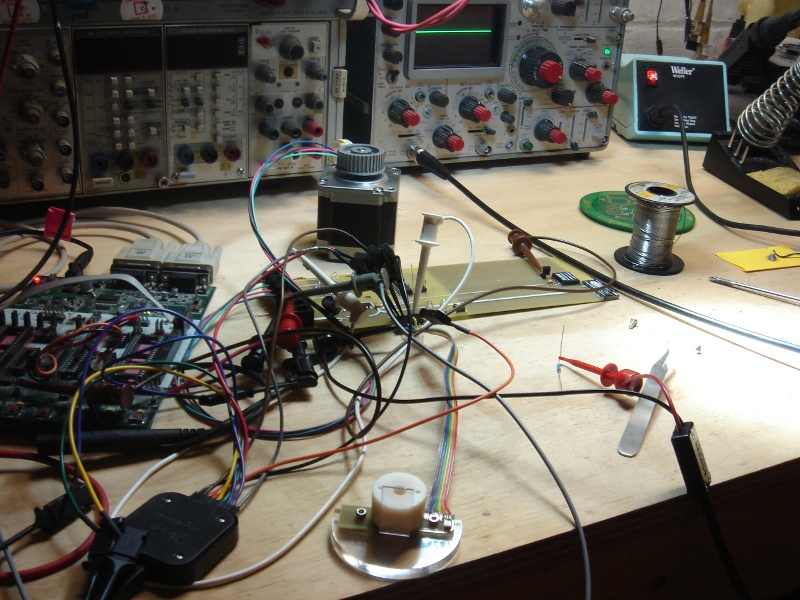

Tuesday, April 19th, 2011Sorry for the short posts. These are long days.

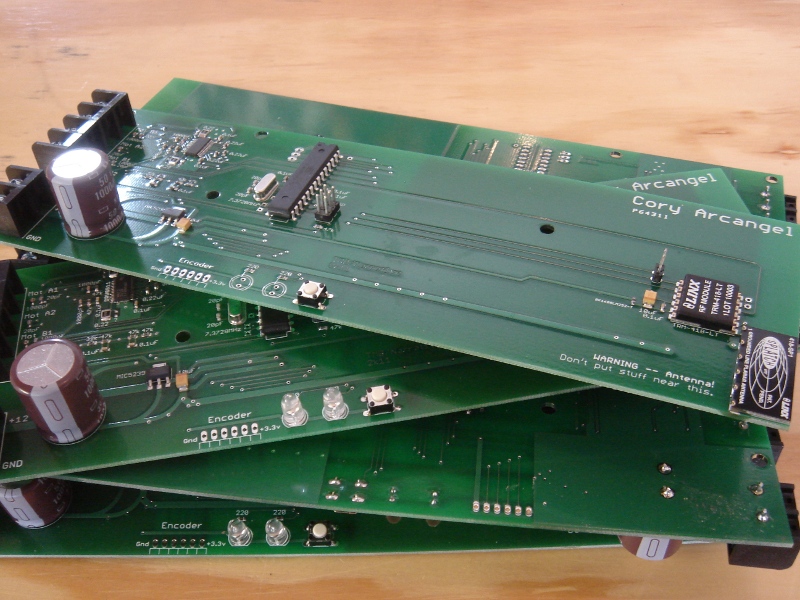

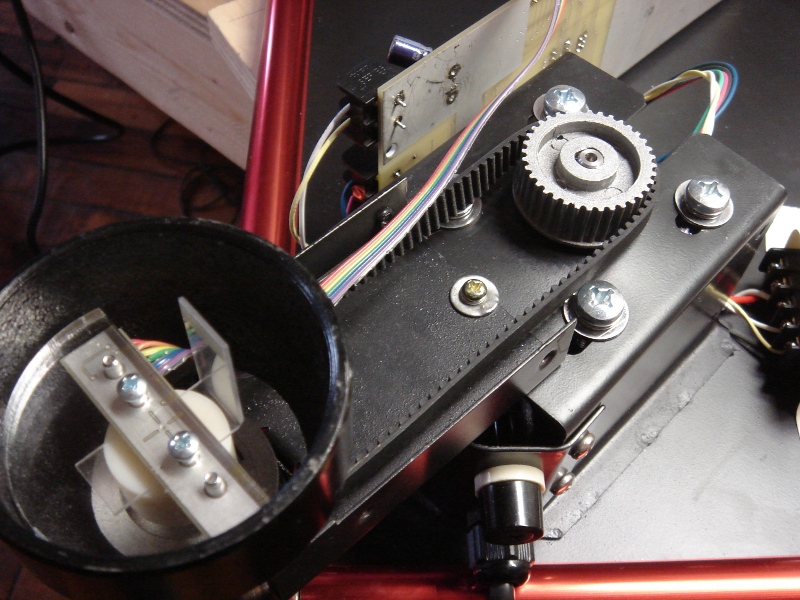

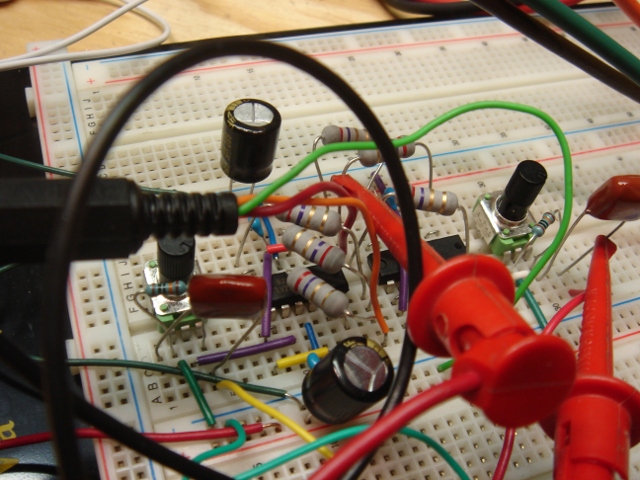

The real dancing stand controller boards are here!

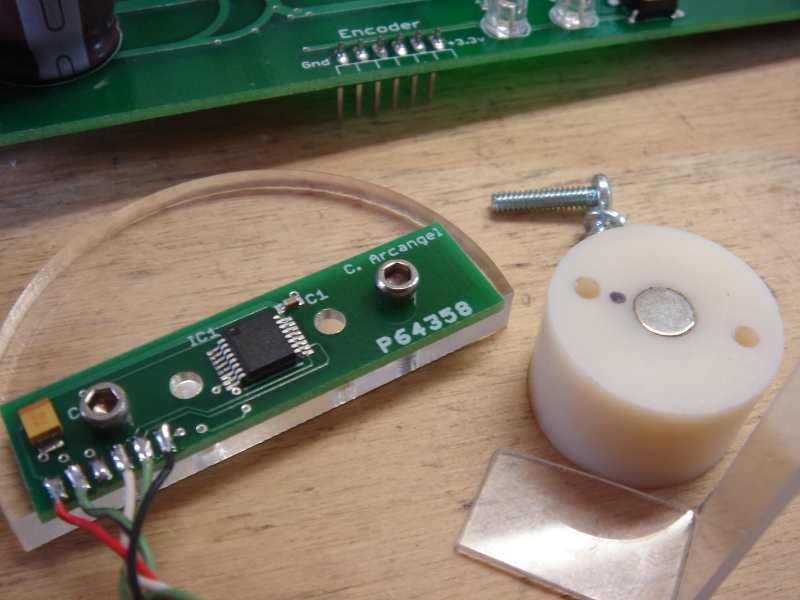

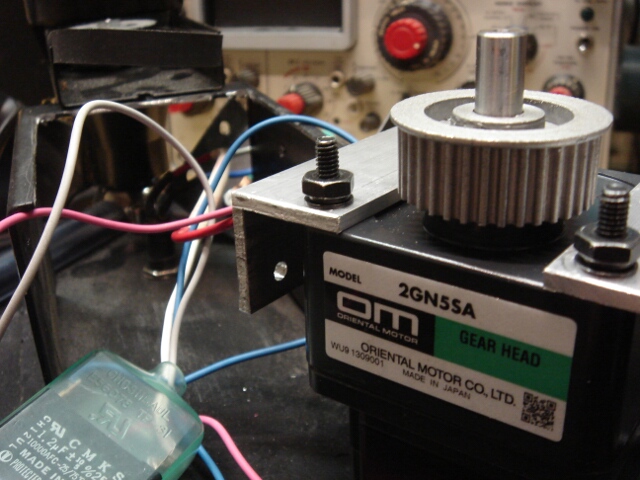

The real magnetic position sensing encoders, too:

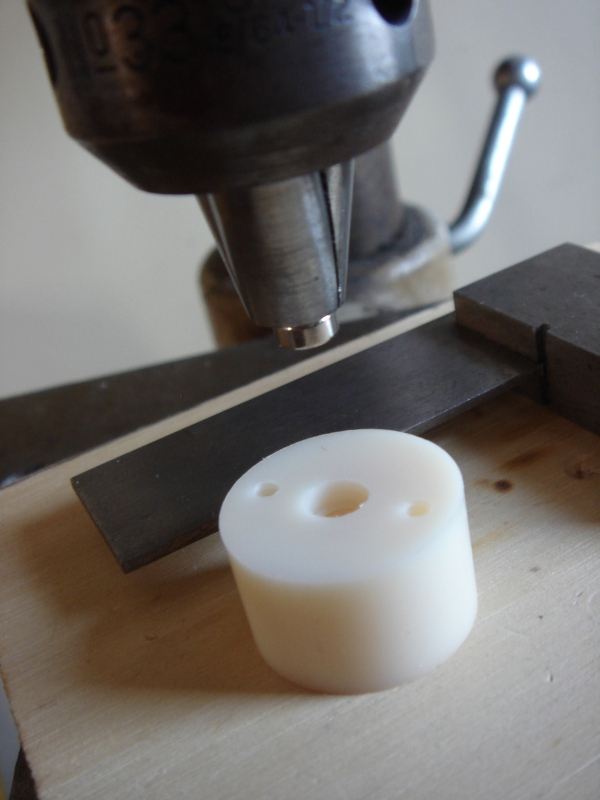

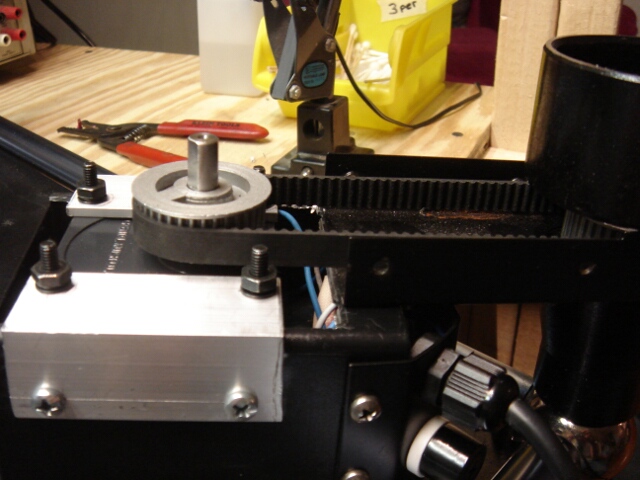

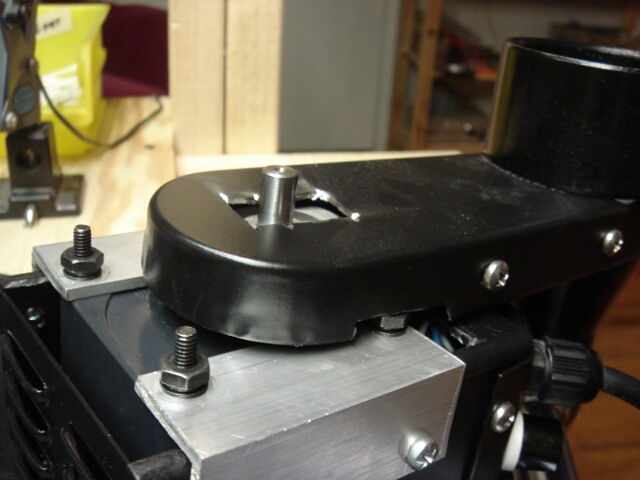

The other side of those encoders is a magnet (read the datasheet if you’re curious — these parts are expensive and awesome and totally worth it), and that magnet has to be centered very precisely over the IC. Any eccentricity or slop or variation in Z height will make for bad accuracy. You wouldn’t guess from the datasheet but these parts are actually pretty forgiving. Nonetheless, I had a buddy of mine (Joe, over at BreadBox Studio) turn me some ABS magnet holders which keep the magnet aligned with the shaft of the stand. They also space the magnet off the shaft itself (the shaft is steel and screws with the magnetic field as the encoder wants to see it) and provide some registration holes. The magnets are press fit into the ABS turnings. Like so:

Thanks, Joe! Now I gotta crank out 17 and make sure they all do what they should. Wish me luck….