WTPA2: Straight Up Struggle

Sunday, June 26th, 2011Last week was hellish.

Srrsly, yo. I forgot how much work this is. I flew my buddy Nick out from Chicago to be in charge of kitting and assembly, and my job was to get the firmware rocking. We had from June 20 to June 24 to stuff 300 kits, 100 jack boards, 100 drilled and tapped enclosure kits, build and test 100 microSD daughterboards, build a dozen assembled units, and get ready for Bent and our Solid Sound panel talk with Moog!

Woes, take 1:

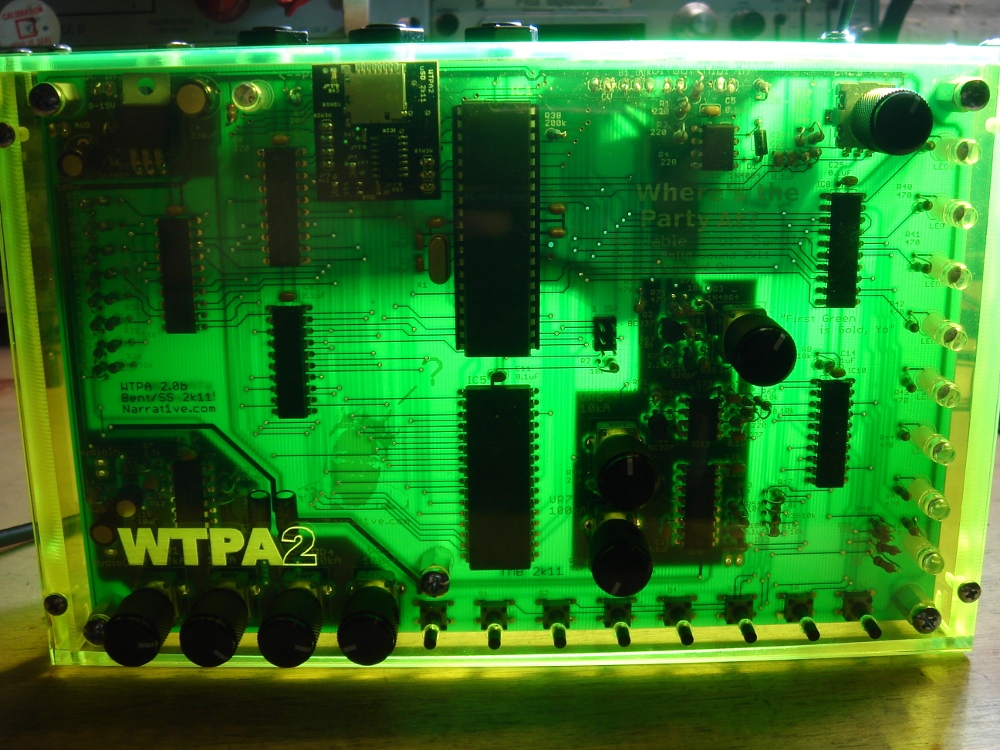

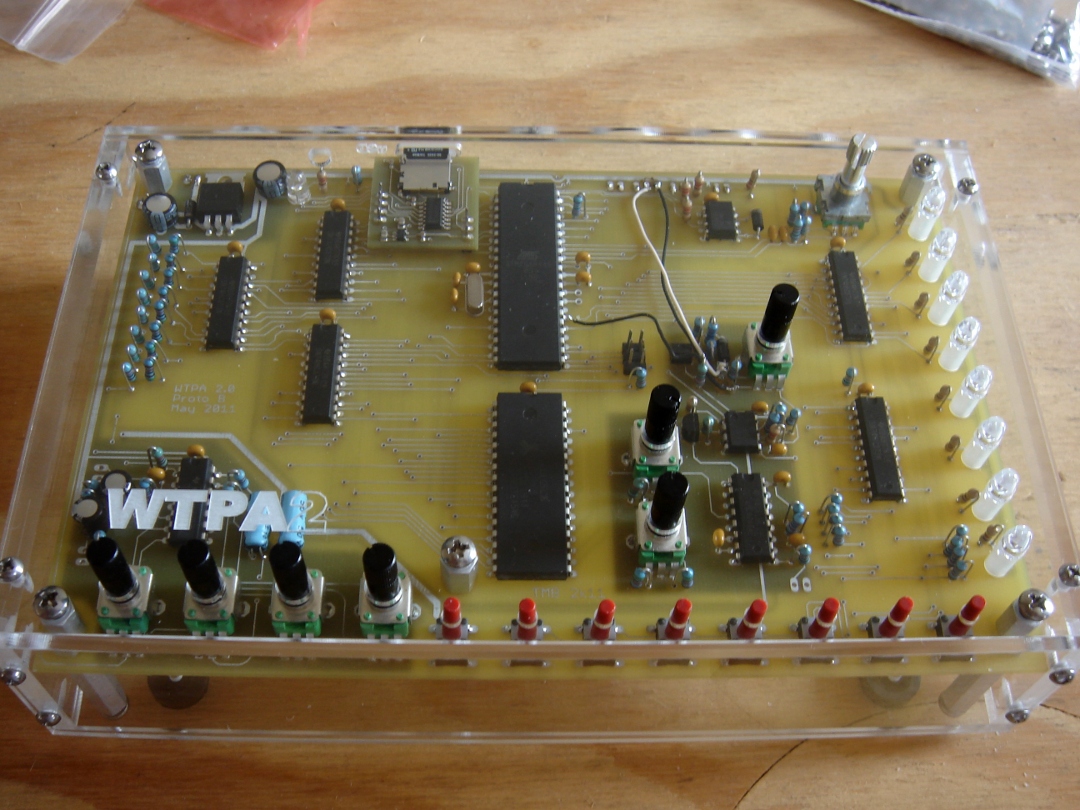

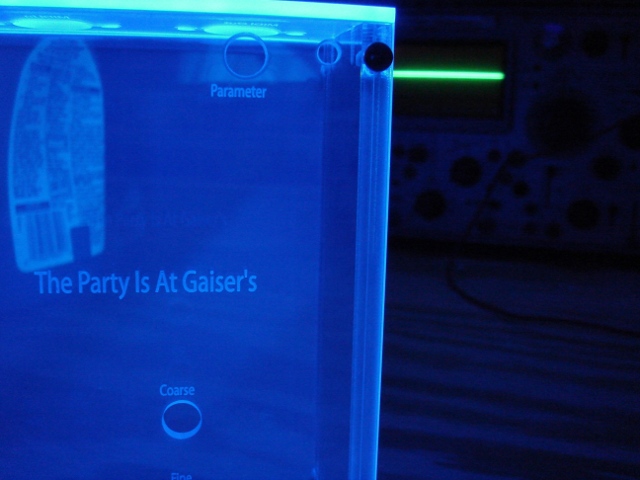

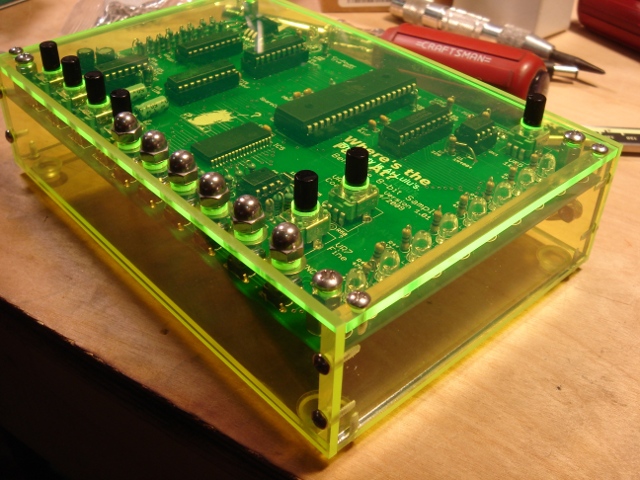

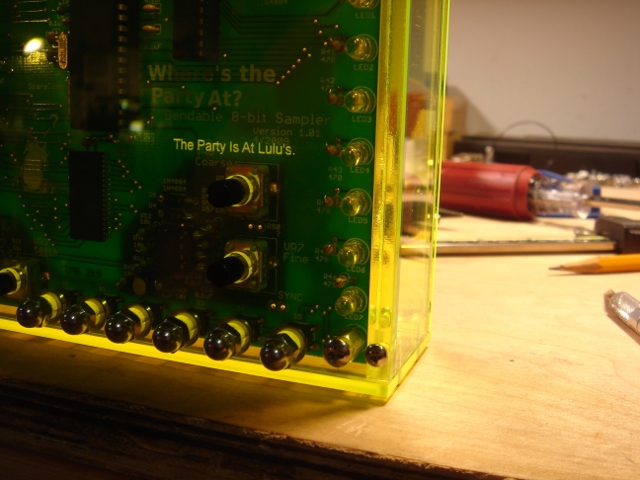

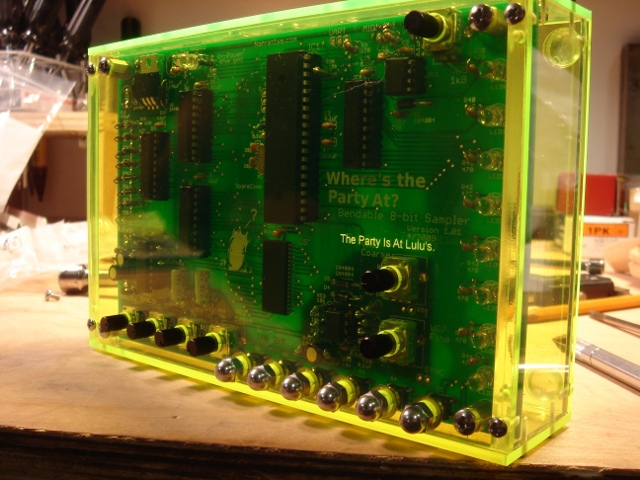

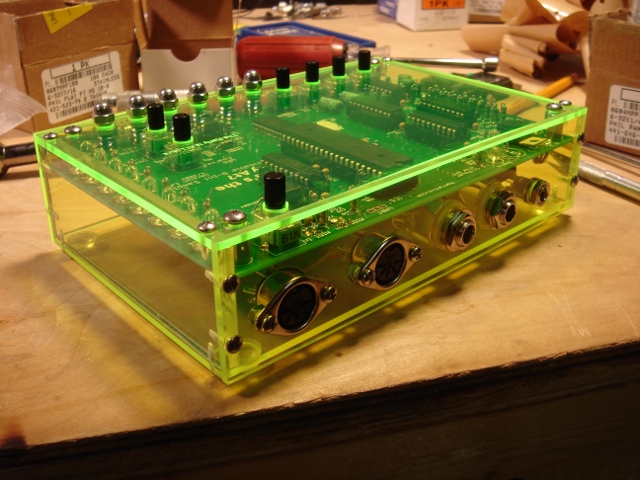

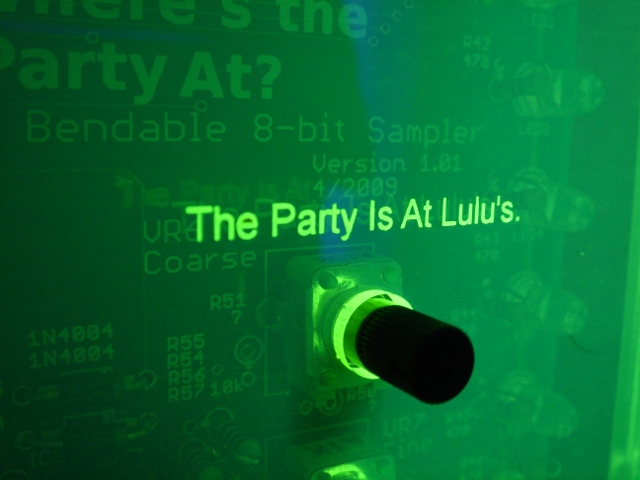

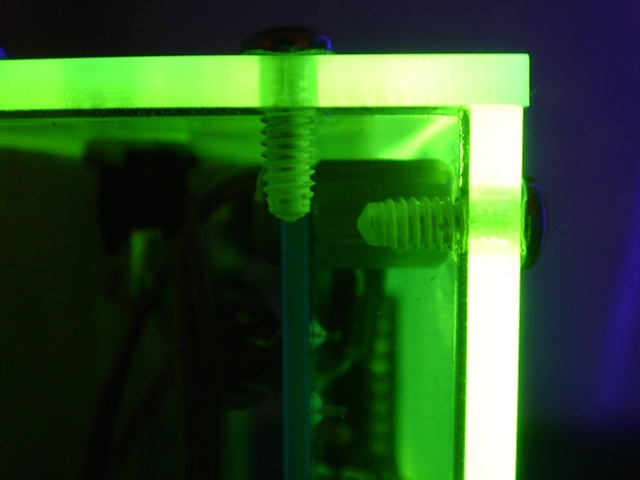

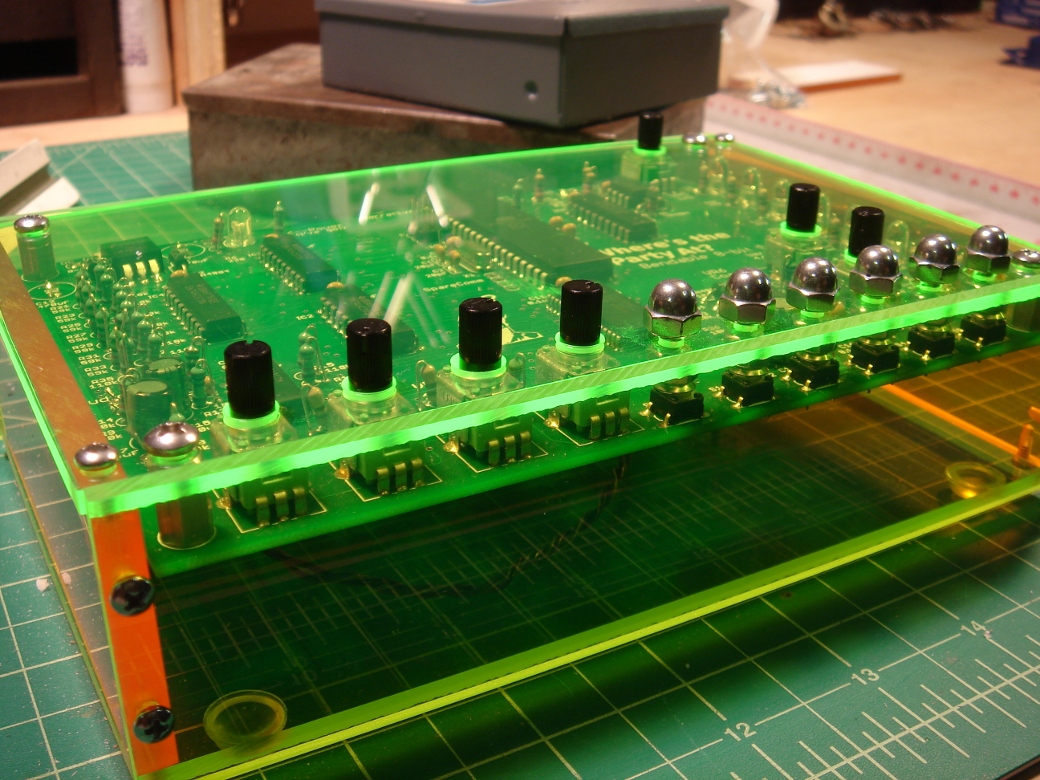

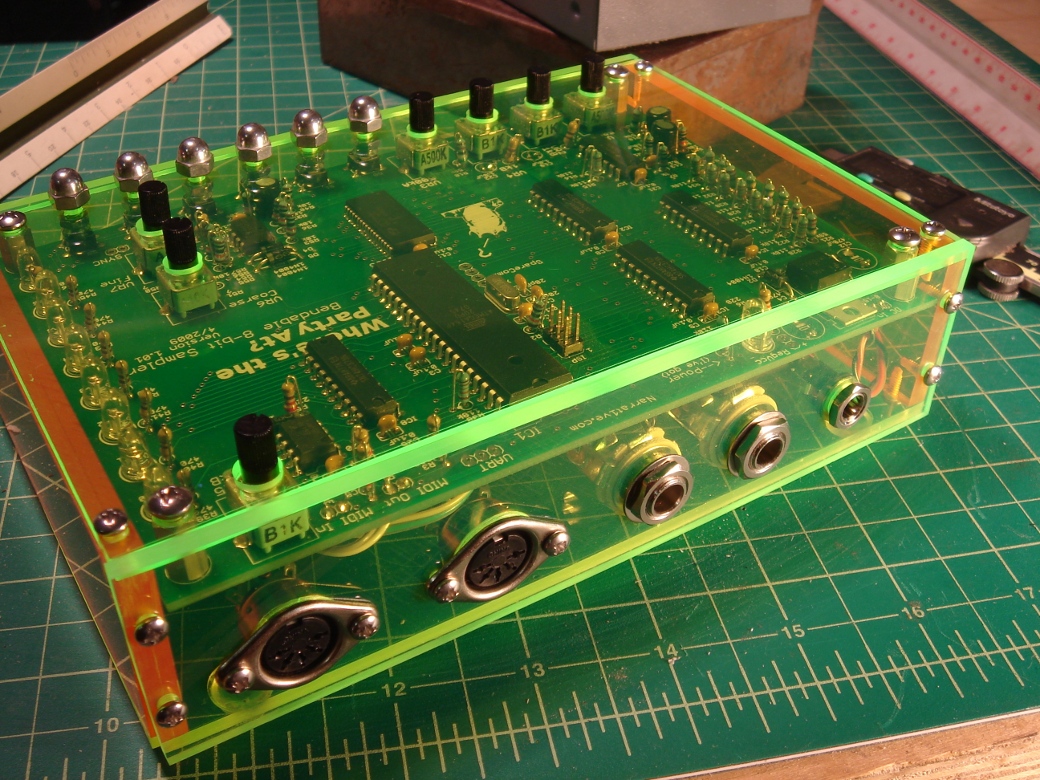

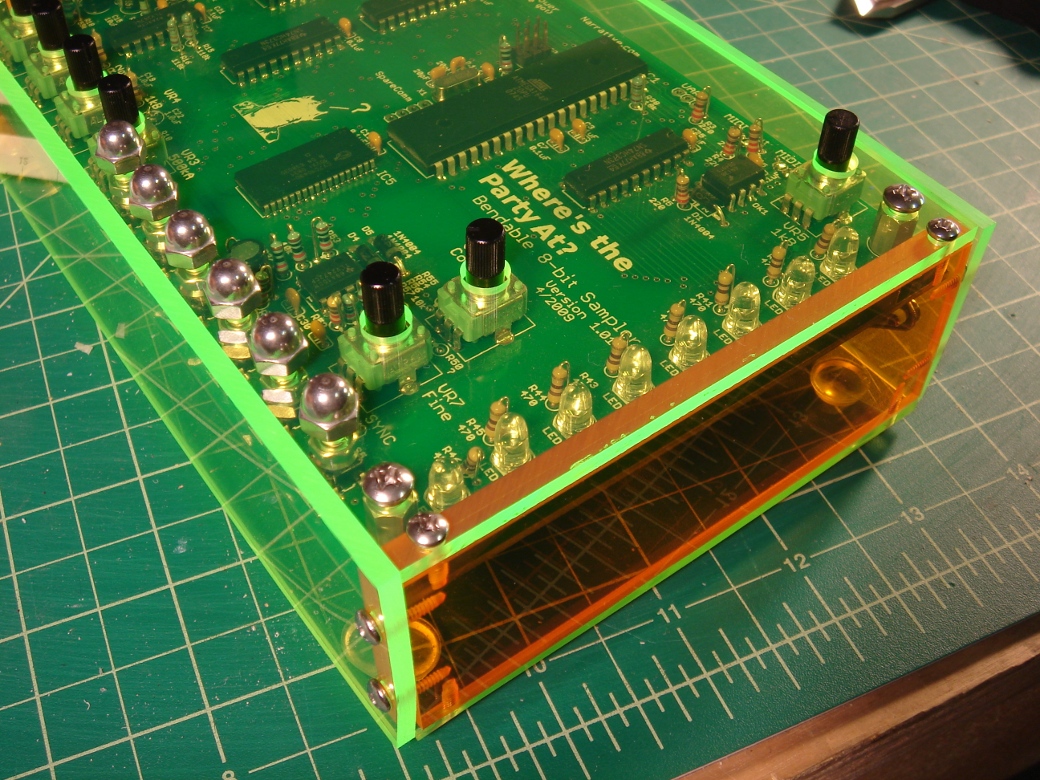

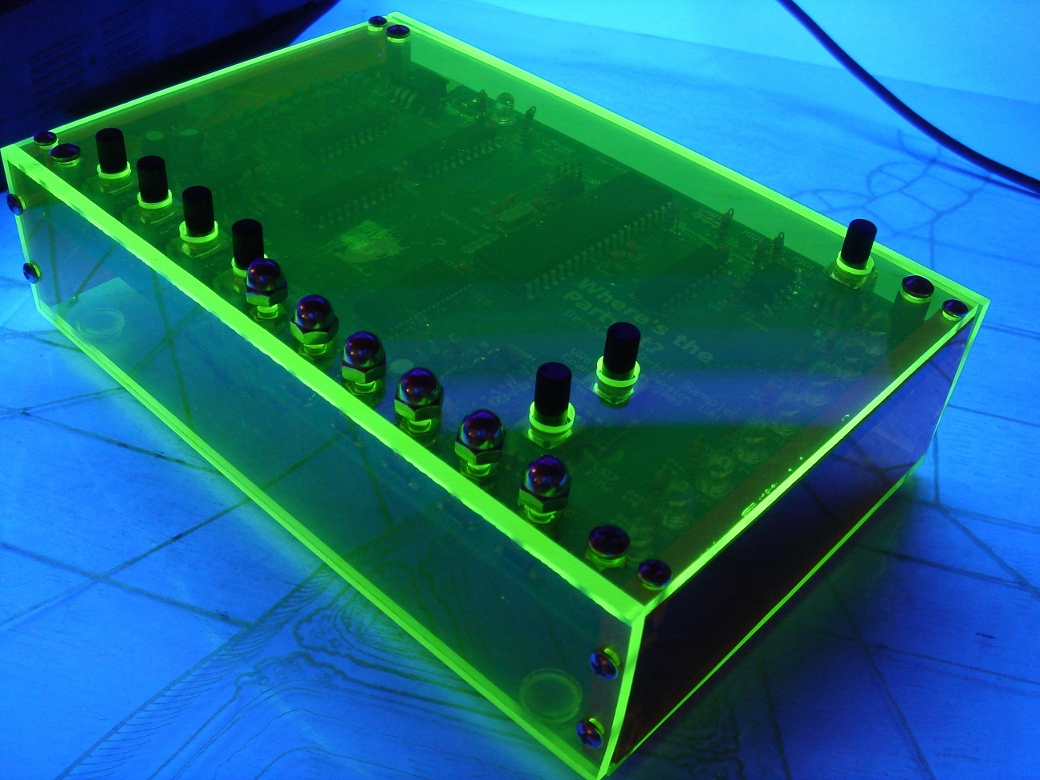

China called and were like, yo man, your main boards are gonna be late. I blame myself for letting it get so close to the wire, and to be fair they were totally sports about shipping the paste stencils and small boards early. Still, with no main boards, I would have nothing to show at the festivals. Eff that. So I called up Advanced Circuits and was like, hook a brother up in the meantime, and they were like BLING BLING. So, I got 27 “Limited Edition” green pcbs, and made some acrylic enclosures to match. Financially, it was retarded. But I have my pride.

Woes 2:

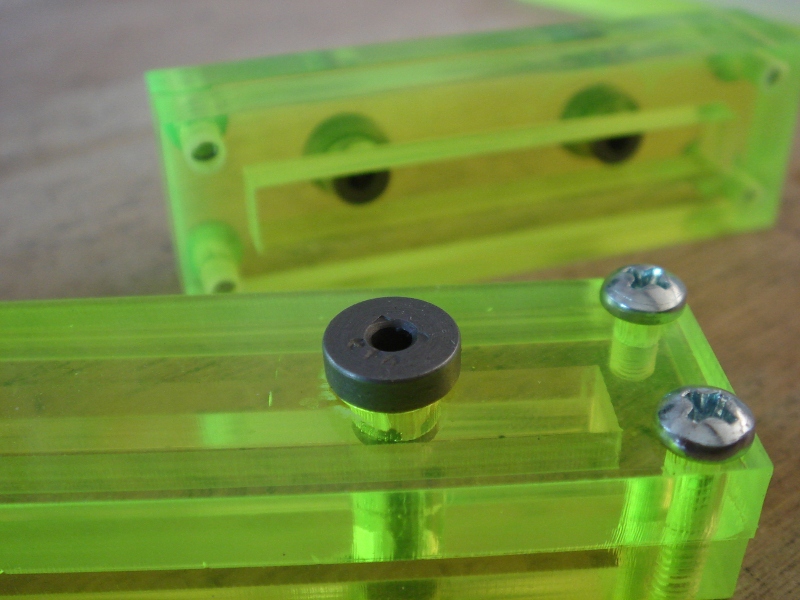

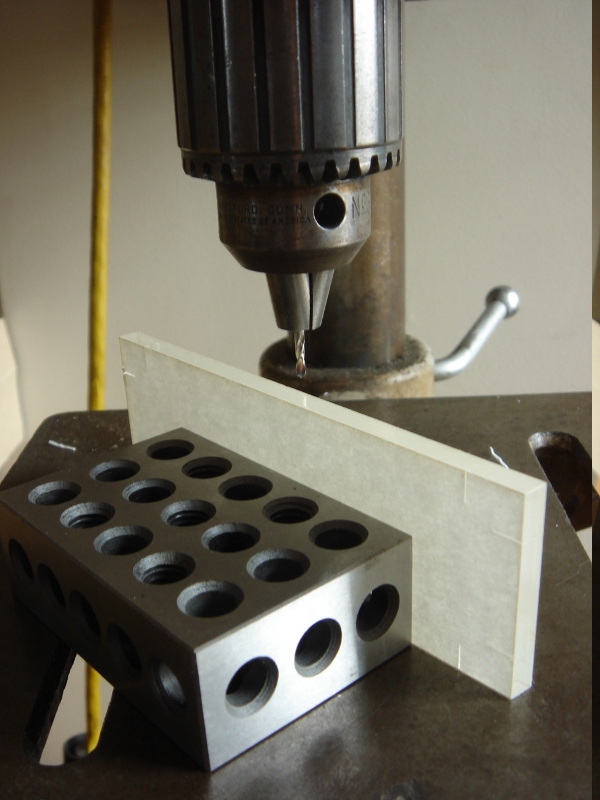

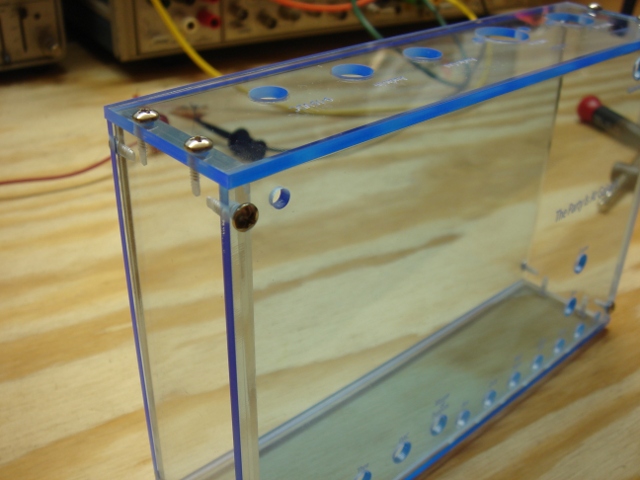

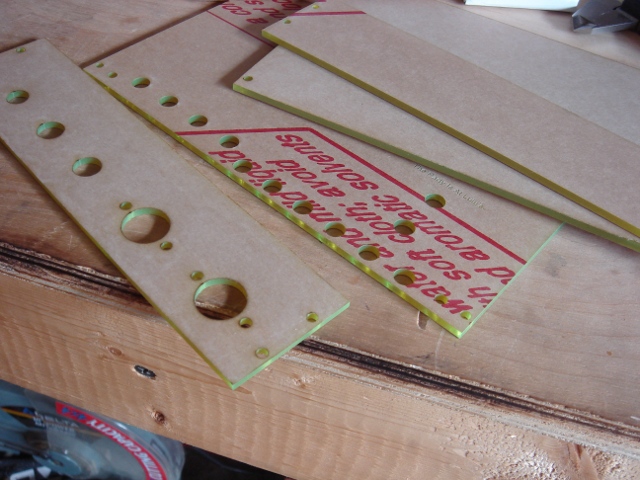

Joe at Prototope really nailed it cutting a ton of enclosures. T&T PlasticLand over by Canal also came through in the clutch with like 100 pounds of fluorescent acrylic with prices that McMaster can’t hang with. However, some dumbass specified that all these enclosures should be drilled and tapped, and those operations alone took DAYS, even with my fancy drill jig:

Here’s Nick hating life:

Woes 3:

That effing pulse shaper circuit (see the last couple posts) was wrong. Of course we didn’t figure this out until an hour before Bent. It was borderline such that it worked _a little_ even though the circuit had not changed since the prototype. The routing and components (though not the component values) had changed, and that was enough. Basically the LM358 had shitty rise times into whatever load the circuit presented, and the effective edge frequency (what the pulse shaper really looks at) was too low to work. I threw a handful of expensive TI opamps into some kits and dragged them out anyway, determined to have something to sell, but I only thought of this after Bent (but before we drove to North Adams for the festival). The new opamps slewed a lot faster and were an effective (if again, expensive, bandaid).

Woes 4:

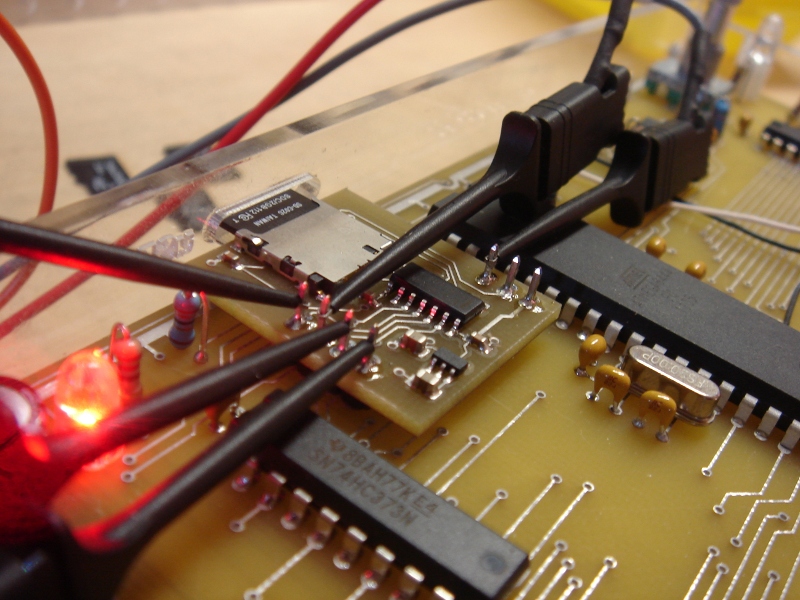

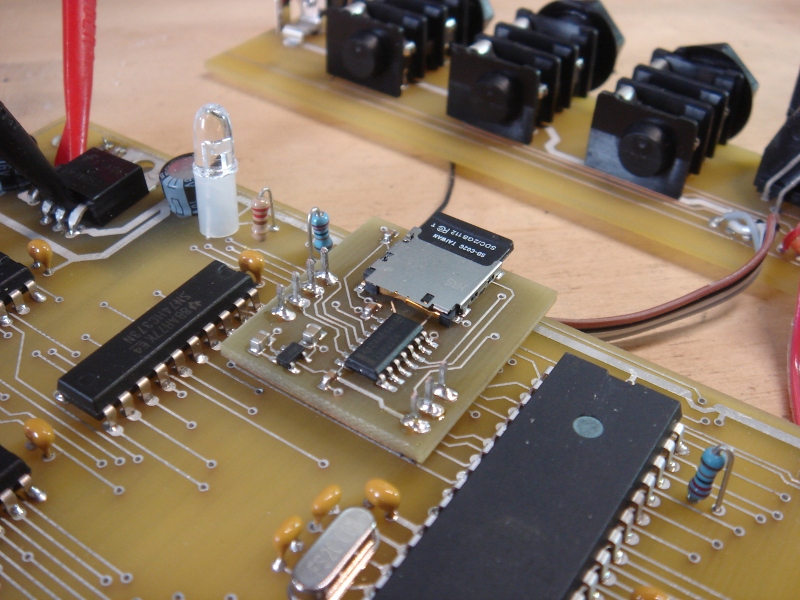

The microSD card. I came up with new swears for these things:

Originally for this project I bought a crappy Kingston 2GB uSD card for testing from a pre-paid cellphone store near my house. FOR WHATEVER REASON, it turned out to be the fastest, most forgiving device ever. This week, on a whim, I ordered every crappy uSD card between 512MB and 2GB that I could find on Ebay. They all behaved differently. It took days to test my drivers to make sure that all the cards behaved correctly, and there are definitely exchanges in there that you have to do which have pretty much zero to do with the SD spec (or at least the free one). This sucked, to say nothing of then trying to make a filesystem and buffers to read audio in realtime. While card access was rock solid for all tested cards by Bent, I kinda though my sample read-write routines sucked. In the end I threw them out. The devices at Bent could format an SD to the WTPA filesystem (which is NOT FAT16, but a more real-timey system that I think makes more sense) and that’s about it.

Woes 5:

Driving to North Adams after Bent with a trunk full of expensive, lovely, VERY PROTOTYPE-EY WTPA2s was the worst experience ever. I’d been up for about 72 hours on about 4 total hours of sleep (none the night before) and I seriously saw animals that do not exist in this world. Anybody who can’t afford bad acid should try writing device drivers for three days while inhaling plastic fumes and then driving through a woods full of deer at midnight.

But then we got there, pounded a bunch of beers with our nerd friends, got pocket protectors from eminent wizard Cyril Lance of Moog and generally had a great time.

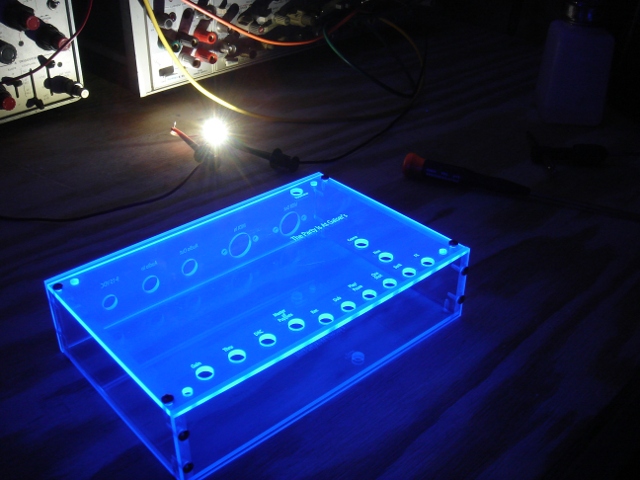

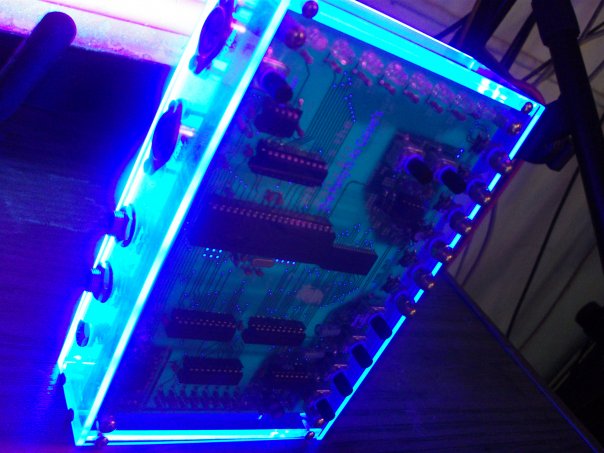

And, oh yeah, in the process we made THIS:

Bent looked like this:

Shop aftermathz:

WTPA2 is not ready to sell, but I have 300 of them and they’re pretty f’ing close. Expect to see the sales link by the end of July.

TB