Component Variation, Or, The Least Sexy Electronics Problem Evar

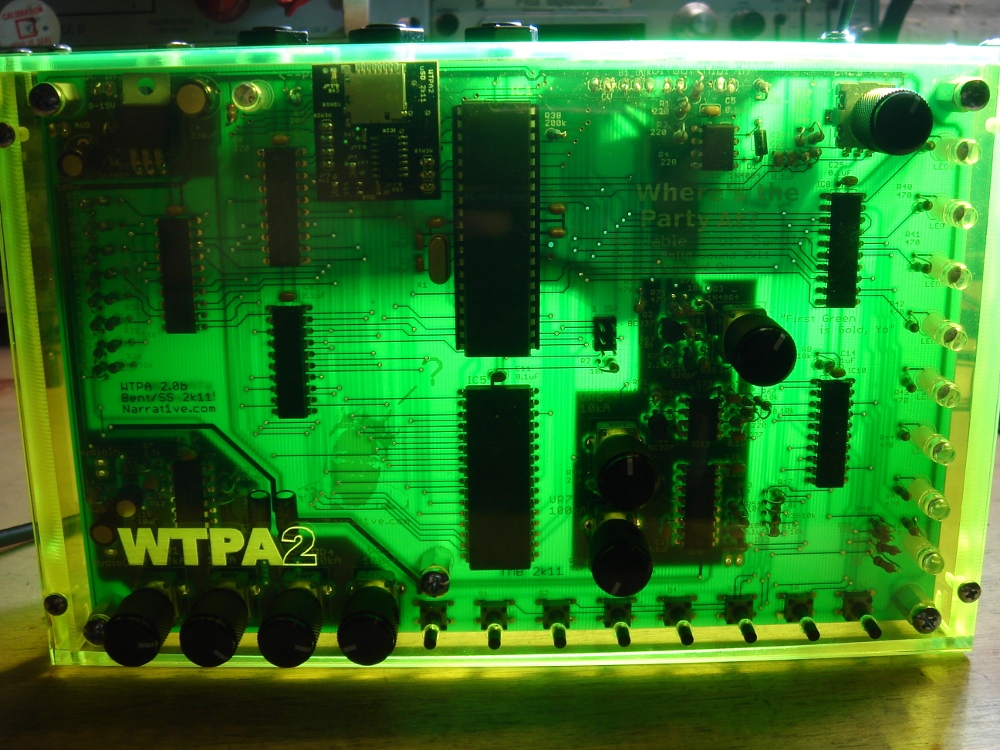

Thursday, July 7th, 2011Analog is sexy, we all agree, right? Embedded systems on the other hand, are full of lots of unglamorous problems. Filesystems, say. Inherently un-sexy.

But I think component variation is maybe the best, most un-sexy problem there ever was. The unsexy cherry on the diet sundae. Like, you HAVE to solve it if you are making lots of something or that thing as a population will suck, even though the one on your bench always ruled.

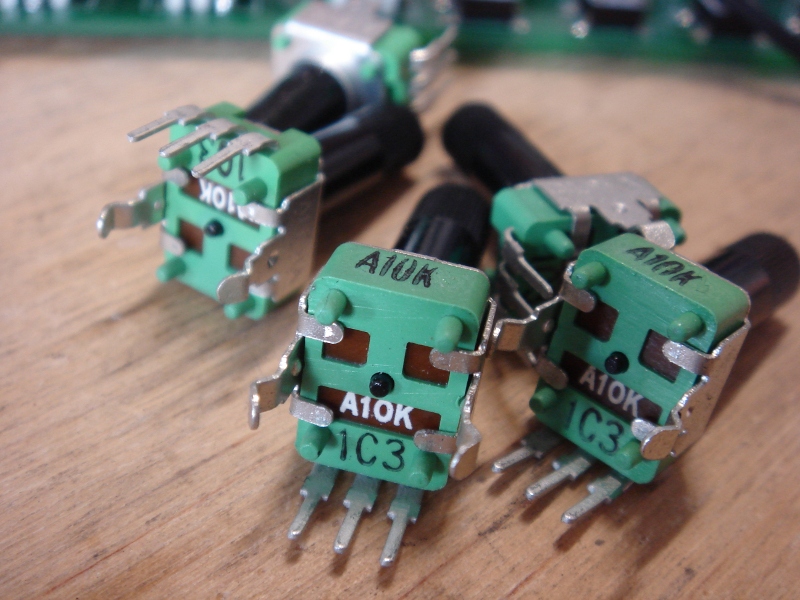

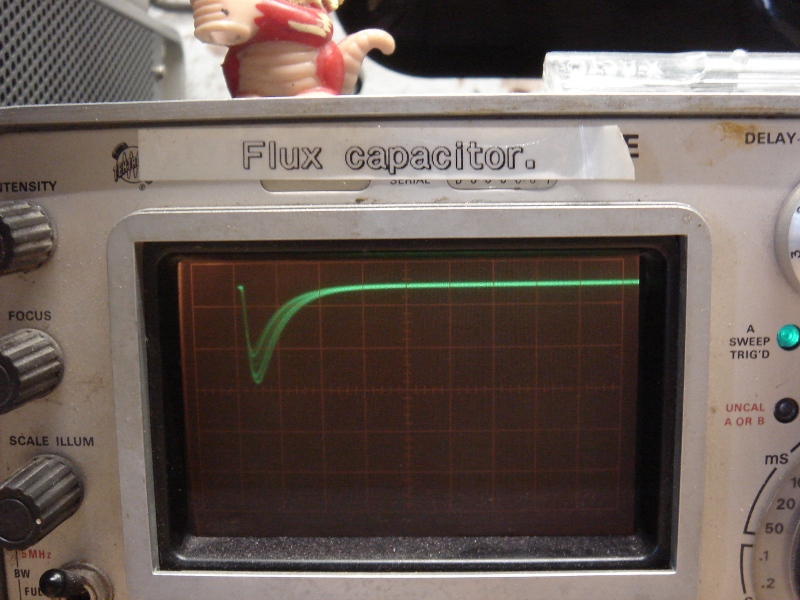

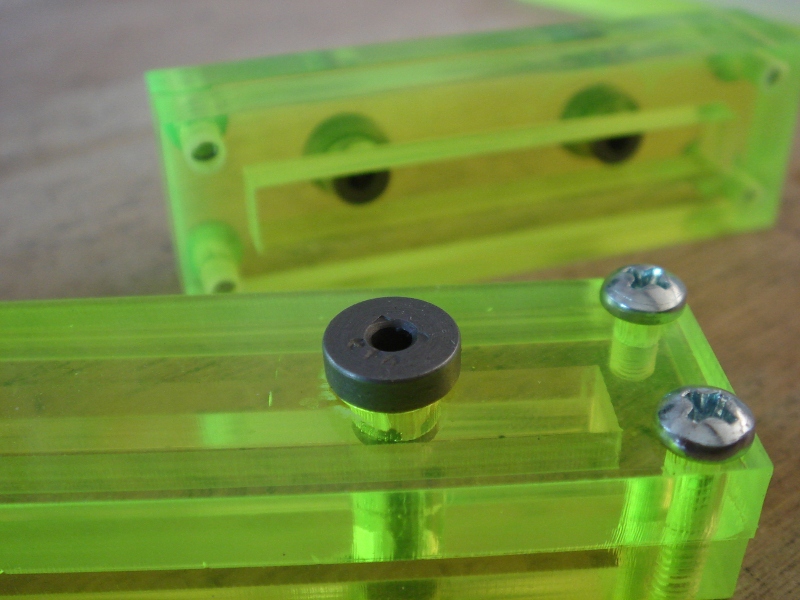

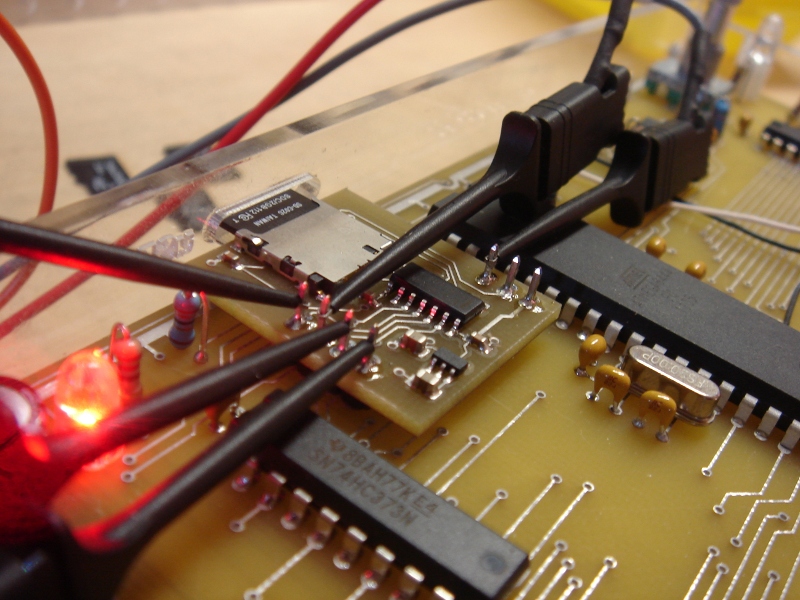

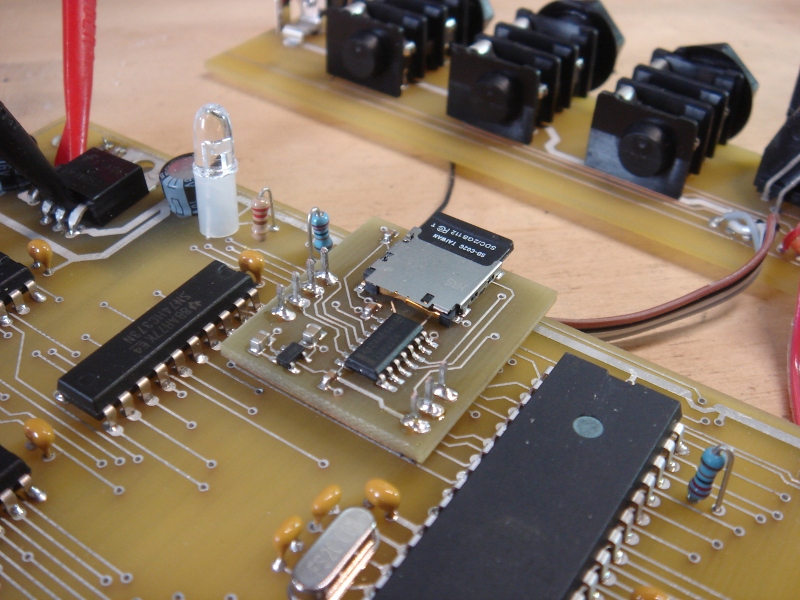

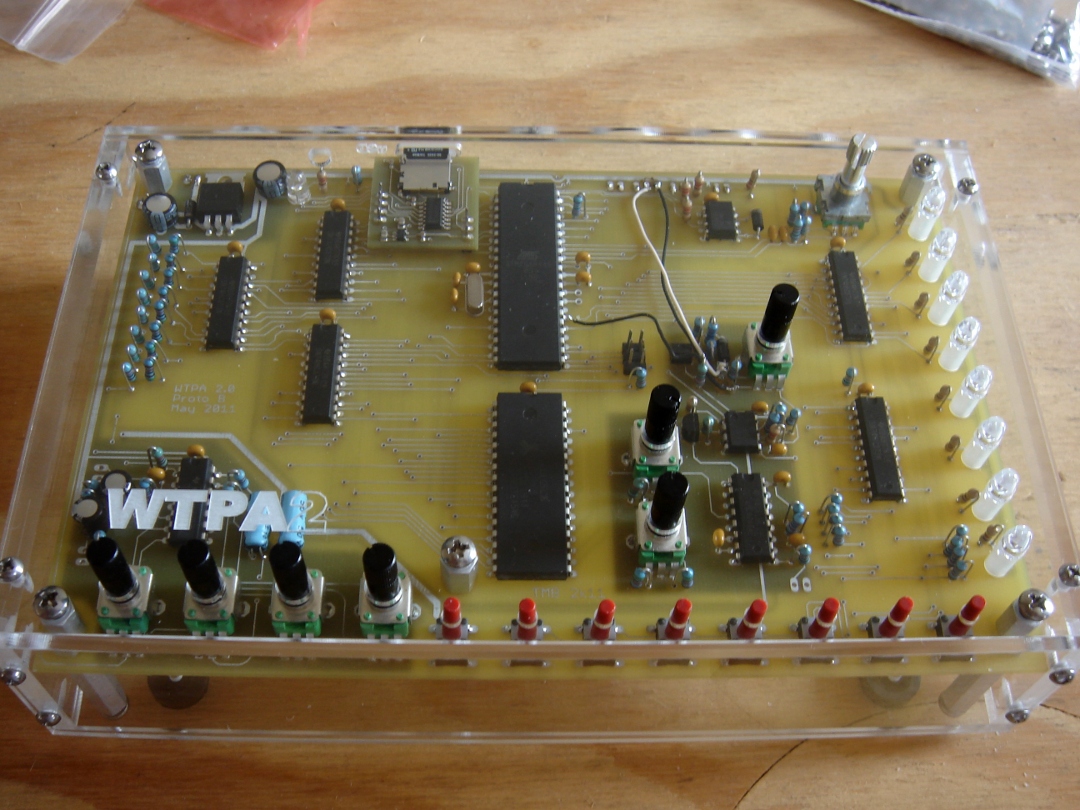

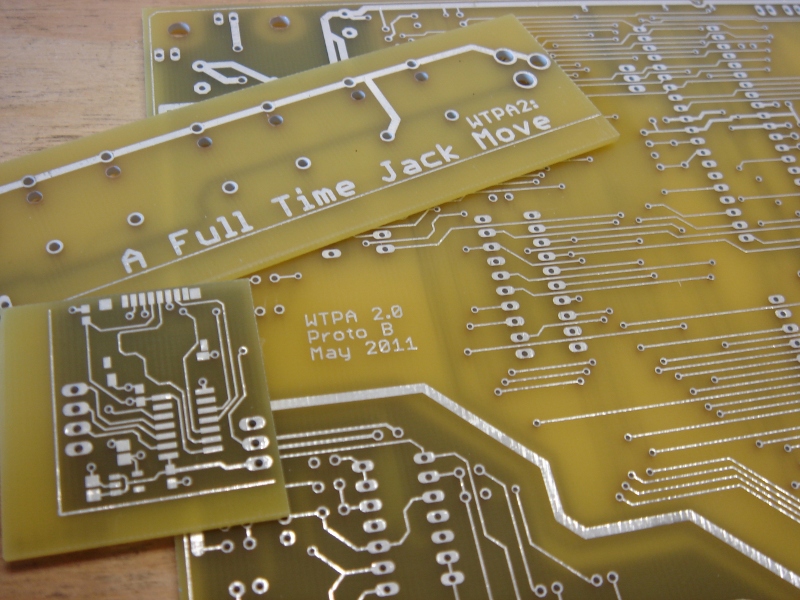

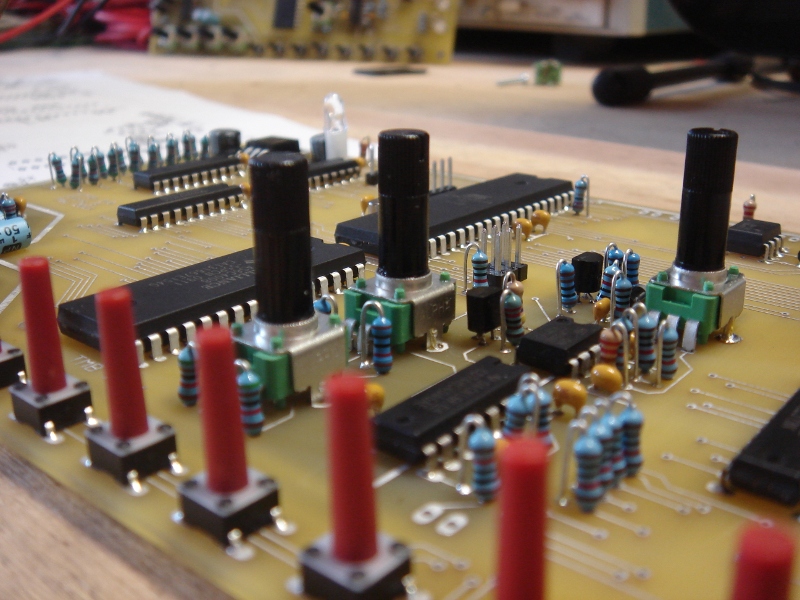

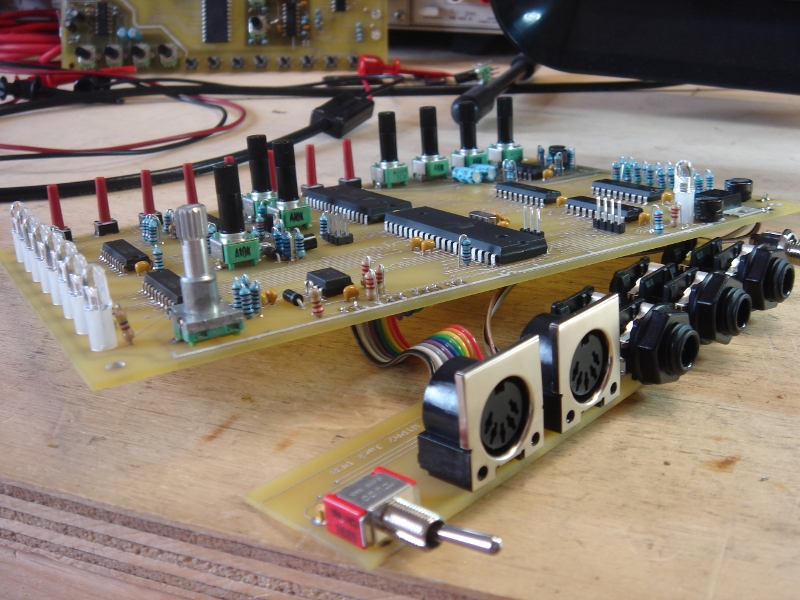

All the pots in WTPA2 are these custom Taiwan Alpha jobbies. There are two values, 10kA and 100kA. The VCO uses one of the 10kAs as a coarse control, and it sets the voltage into a current sink which in turn sets the frequency. I’d been messing with the op amps in this circuit to try and get some performance improvements and “all of a sudden” one of the DUTs didn’t work correctly. At first I figured it was the opamp change, but after a lot of measurement and desoldering and component testing, it turned out one of the 10k pots was really 11.4k. This was a greater than 10% variation!

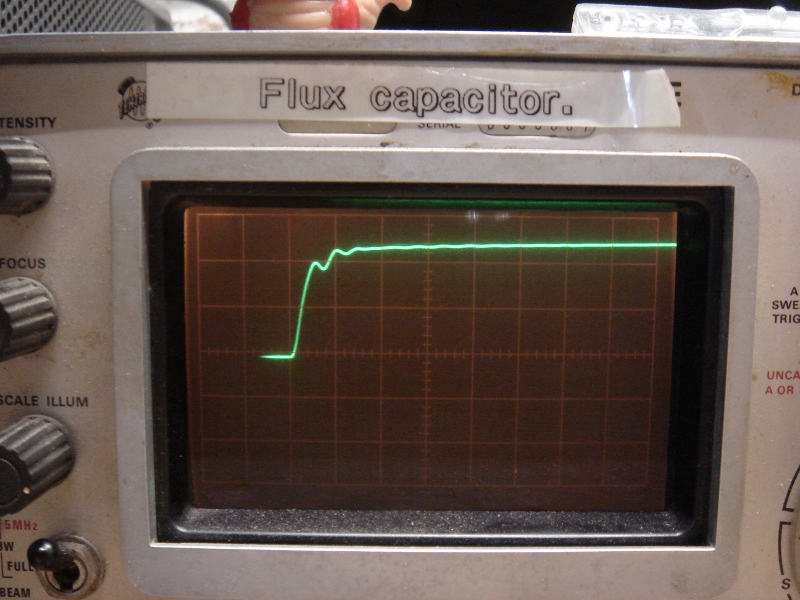

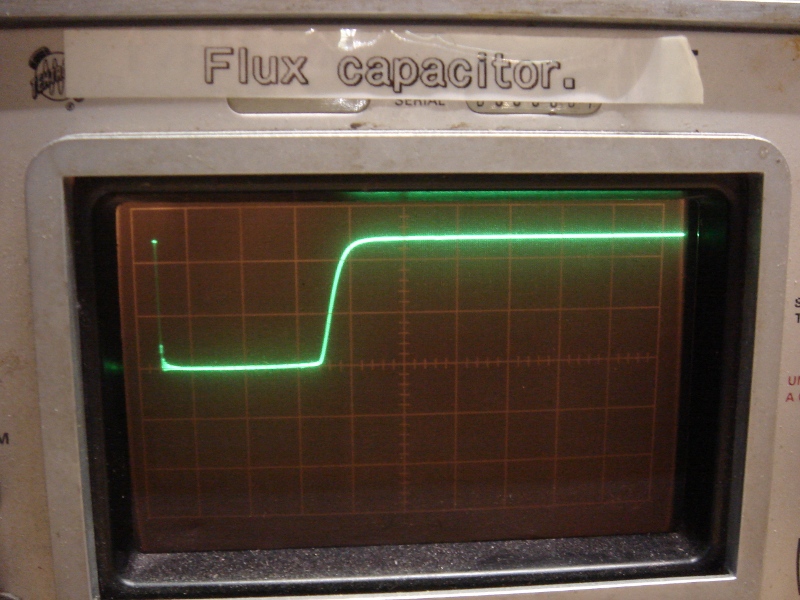

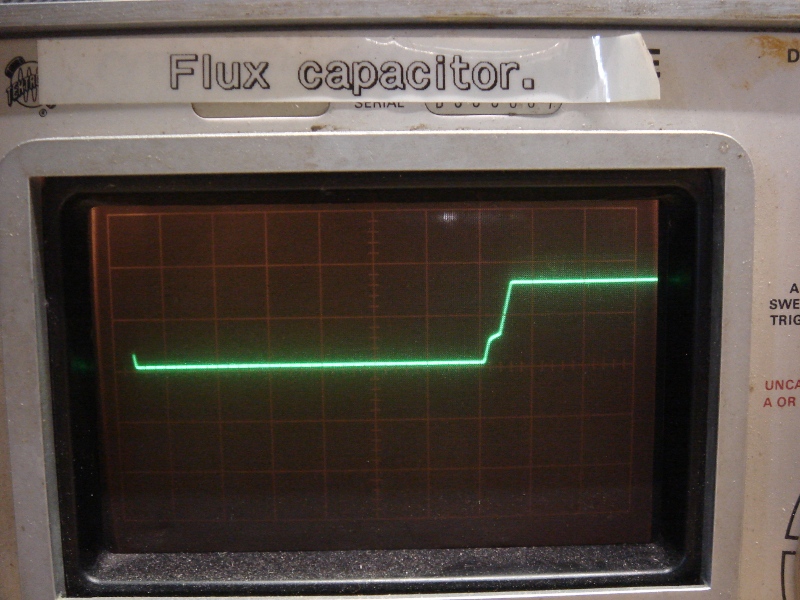

I’d built a margin in for error, but this was above it, and the current sink was getting too high of a voltage. I tested a dozen pots or so from the bin, and all of them were much less off. Still, since one was off, probably another one could be as well. It could even have been a result of the soldering process. I actually bothered to do a DC simulation at this point (using qucs) and fiddled with the component values until they were all as off as I could imagine them possibly being, and then resized the scaling resistor that sets the upper range of the VCO. It was a really crappy annoying unsatisfying solution, because it means that MOST of the units will be operating at a slower maximum clock than they need to. But that one in twelve or one in 100 will work correctly. Serves me right for getting the cheap pots, but there you go. Margin. Component variation.

Least Sexy Problem Evar.

TB