Dancing Stands Get All ED-209

Monday, June 7th, 2010

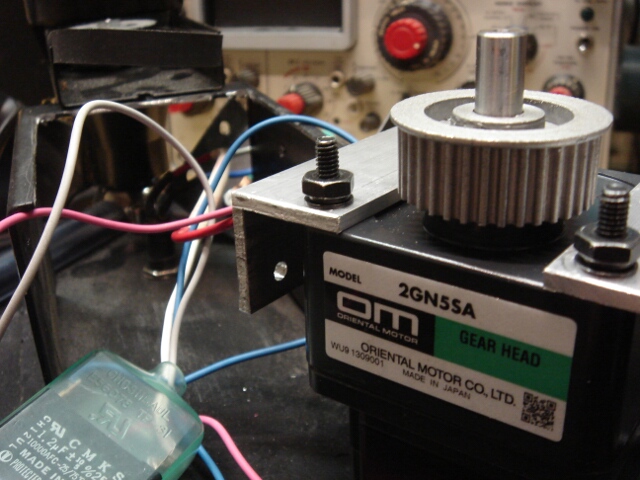

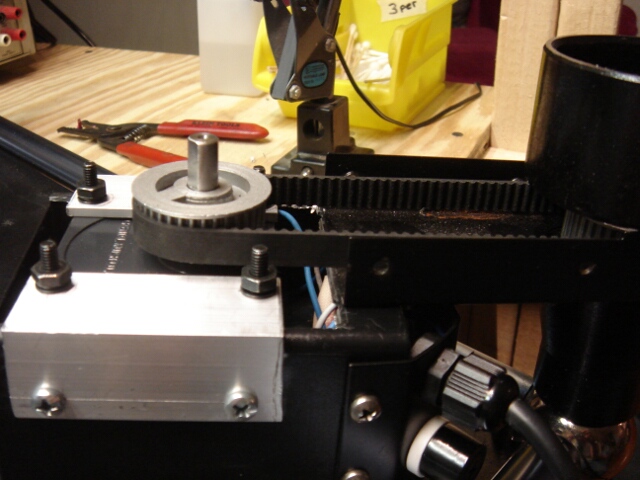

So, because it isn’t actually in a show yet I can’t talk about what this new dancing stand is for, but it may or may not be capable of beating up Robocop. Suffice it to say, the old gearmotor has been removed from this stand and replaced with a two-pound tank which comes as a separate synchronous motor and gearhead.

This also continues the fascinating if slightly worriesome Spring 2010 trend of my clients viewing me as a one stop for assembly language and abrasives, but things are slow so I’ll take it.

The new gearmotor was similar in size to the old one, but not so similar that it didn’t mean cutting out a big piece of the steel doghouse, making some aluminum mounts to hold the motor, drilling out the timing pulleys to fit the new motor shaft, and putting a detent in said shaft to seat the set screw. I also got my first set of metric taps, so that I could use M4 screws in this guy and the hardware I put in would match the hardware from the factory. This, O art world, is the attention to detail you get when you hire C Programmers to get their thread-cutting on.

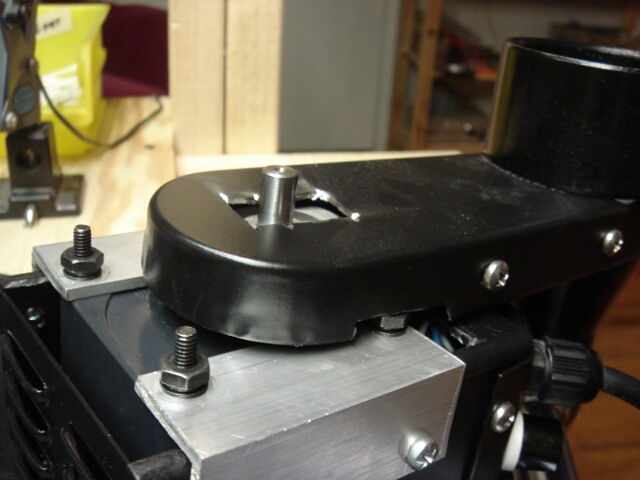

Here she is all buttoned up.

Though I have a sneaking feeling Cory doesn’t really care about what the bottom of these things look like, I kinda do. Plus I figure the dust cover, you know, keeps dust out. Plus I had just gotten these really cool carbide burs and I was excited about cutting more holes in stuff.

Perhaps one day, one of these things will have a stepper motor or optical encoder or SOMETHING with silicon in it and everything will come full circle.