WTPA2 Prototype “B” Totally Running Shiz

Thursday, June 9th, 2011Prototype B is up and running–

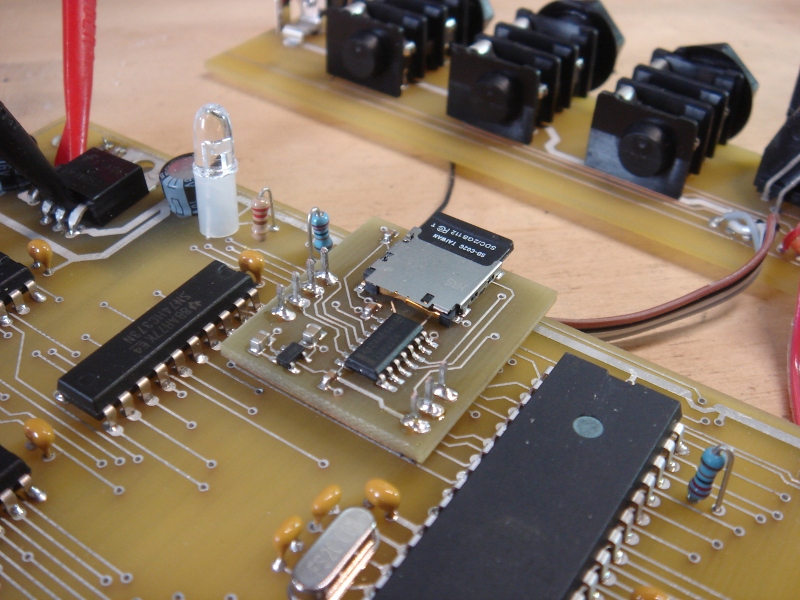

MicroSD, well, fits at least and the card-detect switch works:

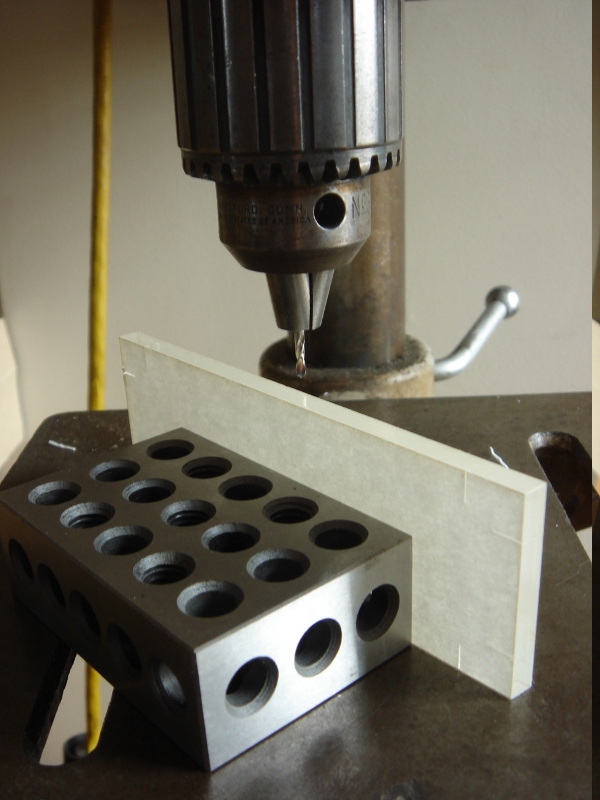

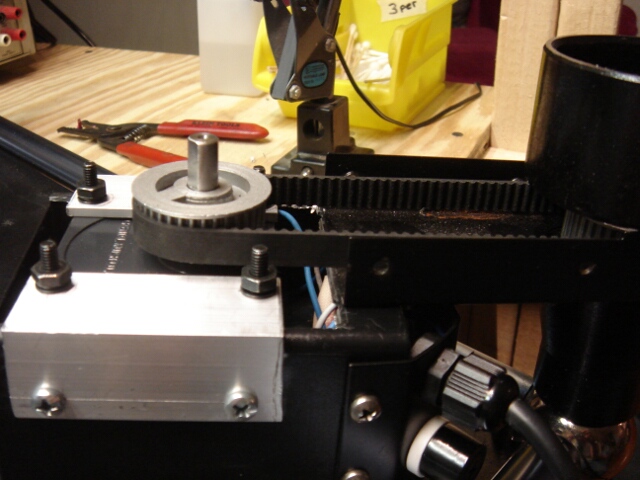

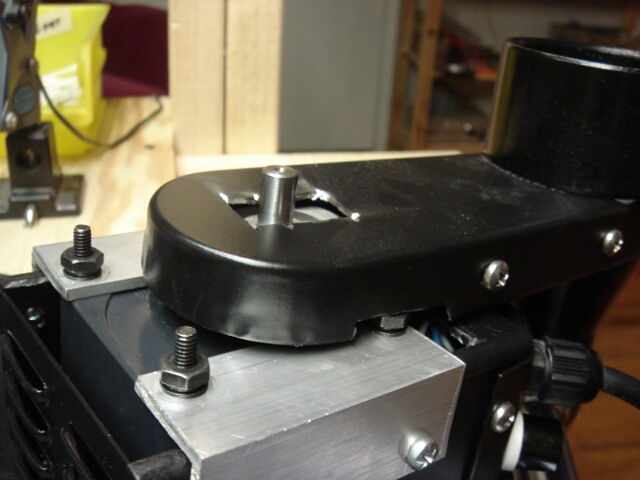

The enclosure getting tapped:

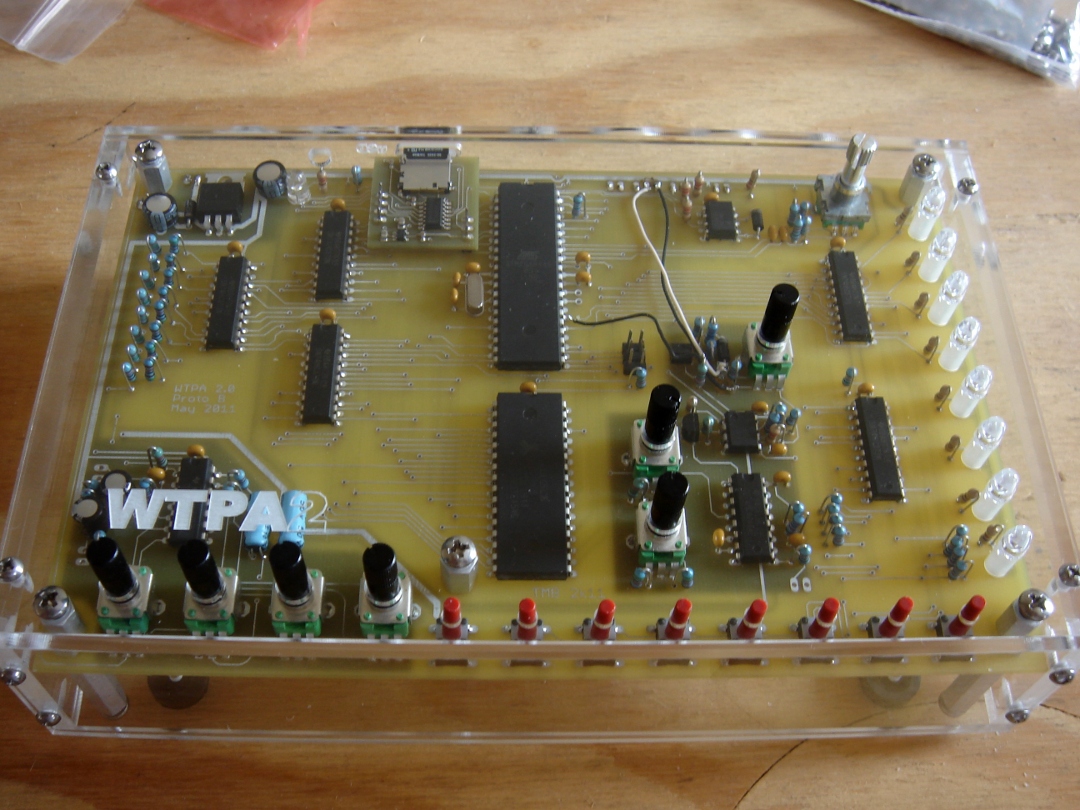

And the pretty views of the done project:

I’ve found at least two dumb problems so far. The Audio In/Out jacks were interchanged in the harness, and the clock select switch was in the wrong place in line for the pulse shaper (only the RC oscillator was getting its pulses shaped before heading to the IRQ pin). Also I cannot seem to find a screw that is meant to mate with those MIDI jack mounting holes. There’s probably more that’s wrong. Once I am sure I’ve found all the bogeymen, I can pull the trigger on the final PCB order.

The uSD card is already being a bitch.

Holler,

TB