So sometime at the beginning of 2010 the sick children of Chicago set up a fuss looking for their monster again. You could hear them all the way from Brooklyn. Again, my guilt was heavy. Again, I made some stuff.

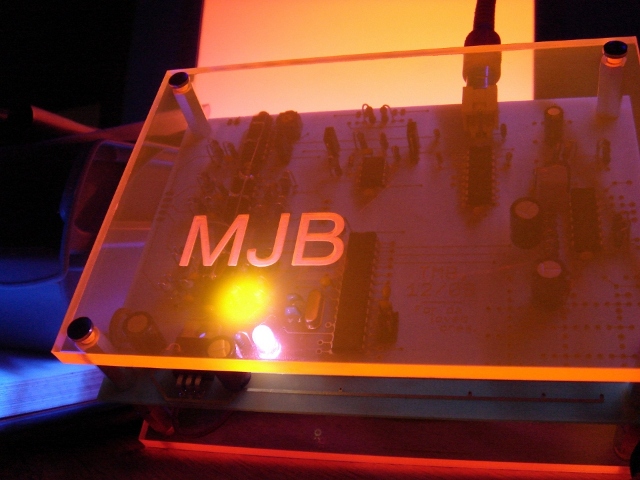

An introduction of what Remoc does is in order I guess. He’s basically a bigass toy that senses when little kids touch him in different spots and plays various games with them. He laughs, he cries. He may or may not be better than Cats. He also goes to sleep at night, sings songs, and has a weird interactive thermometer. He farts a lot. When he behaves, he’s kind of fun.

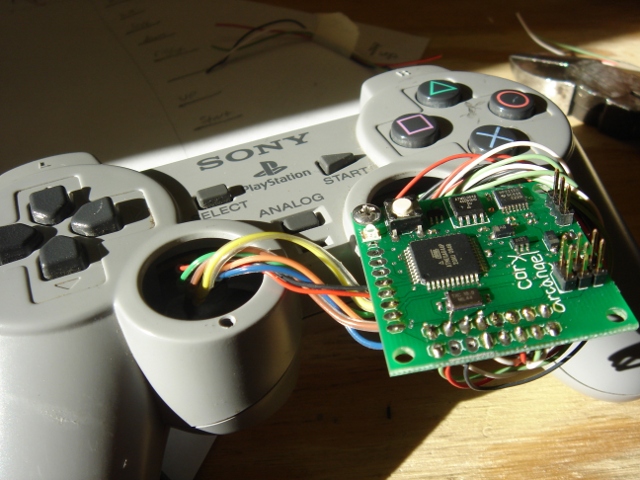

His memory and play pattern live on an SBC designed by my buddy Todd Squires which we used at the old toy company and affectionately call the toybrain (version 4). The TB4 was fine.

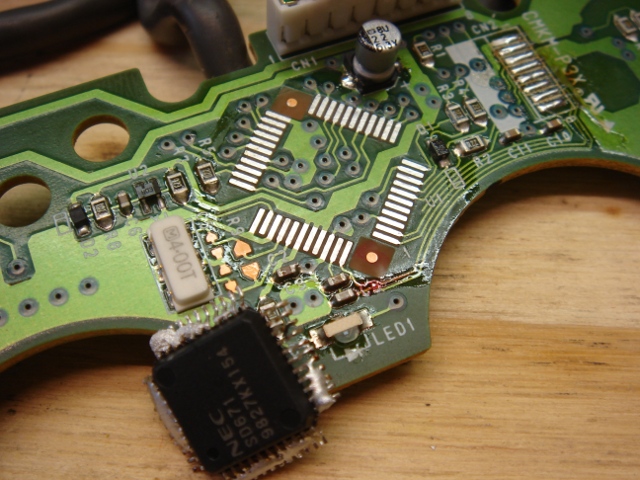

There was no real way to salvage most of the rest of Remoc’s old brain. There was a crappy class AB audio amp I put in which got way too hot, his touchsensor circuits were noise prone and also temperature sensitive, and his LED supply tended to go out of regulation when too many lights in the thermometer stayed on, and he got confused easily about time-of-day stuff if you turned his supply off. His eyeballs were light bulbs which burnt out (that was a committee decision, but). None of this was good.

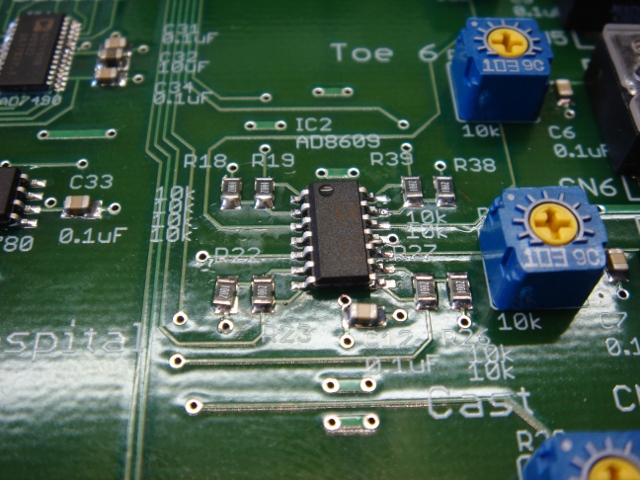

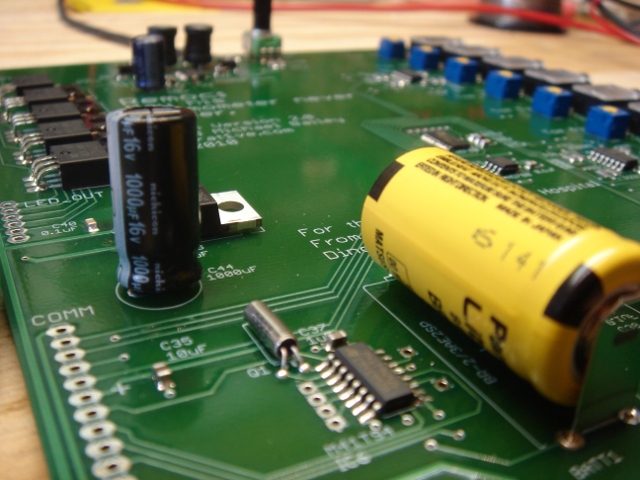

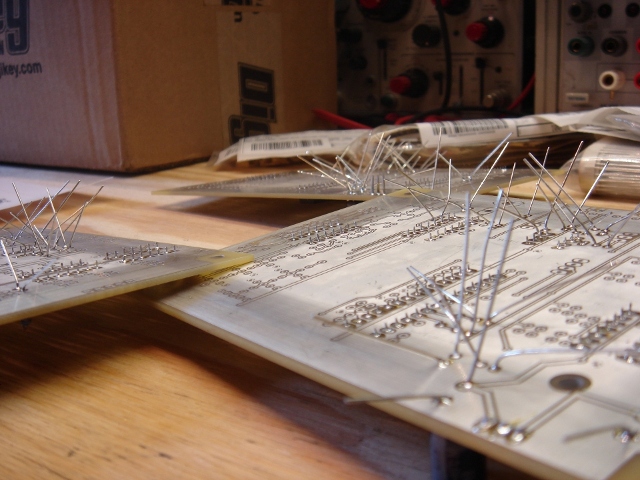

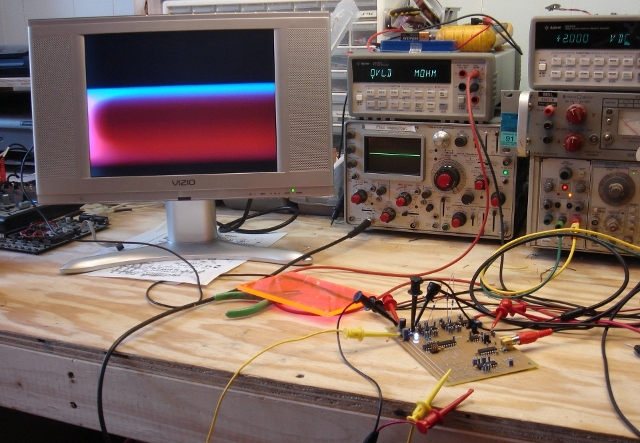

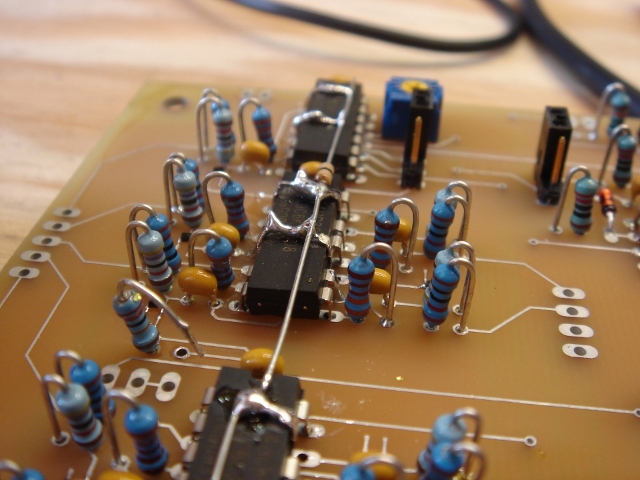

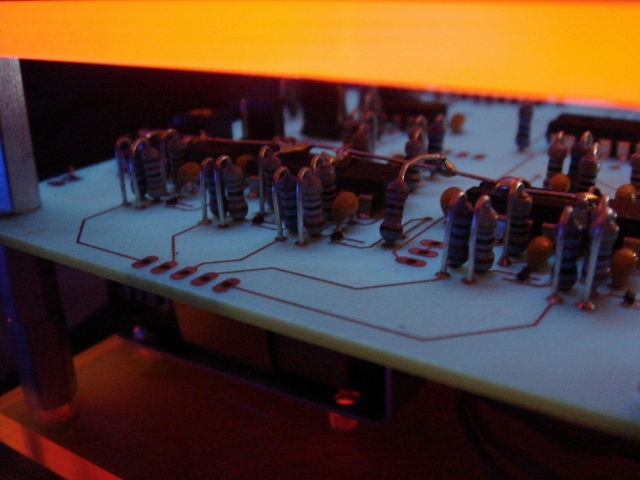

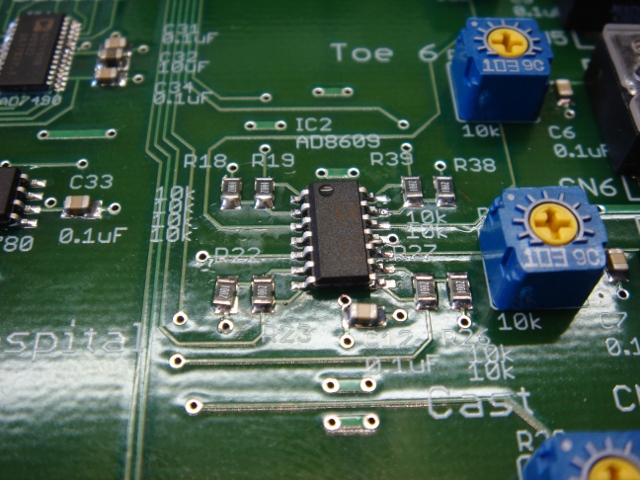

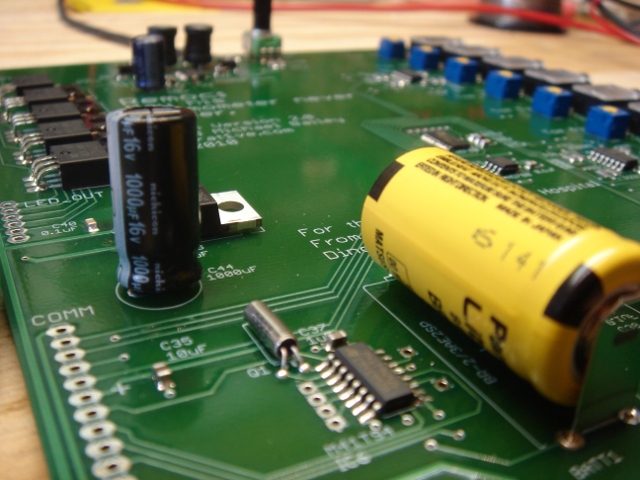

His new brain boards (above) dealt with all this stuff. 2010 saw Remoc get new MOSFETs to run all his lights, a new audio amp, and a proper RTC with a ginormous battery for backup. More importantly, he got a bunch of precision opamps and a multichannel ADC to handle input from the touchsensors.

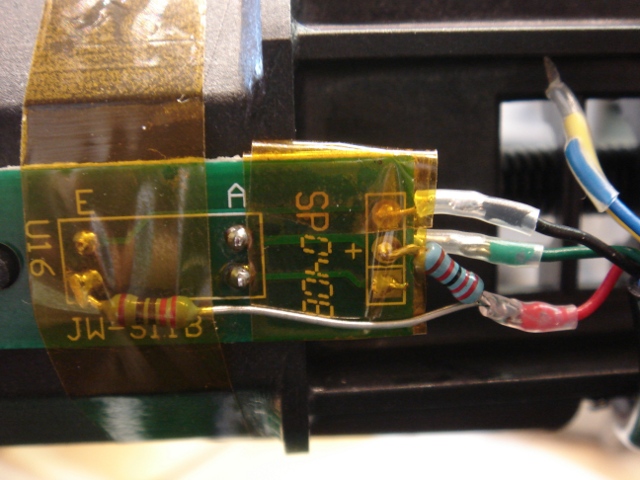

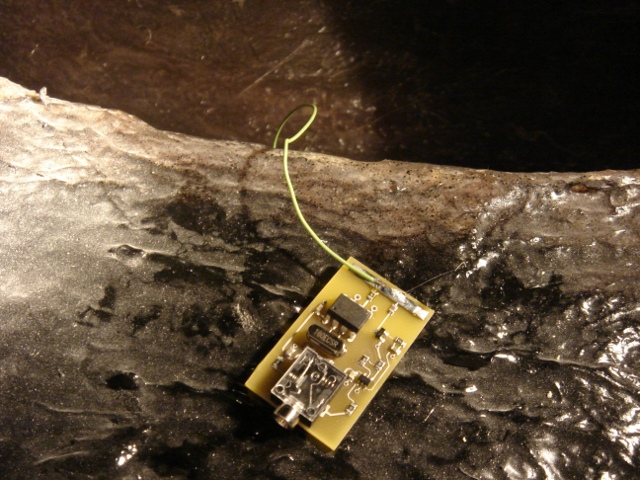

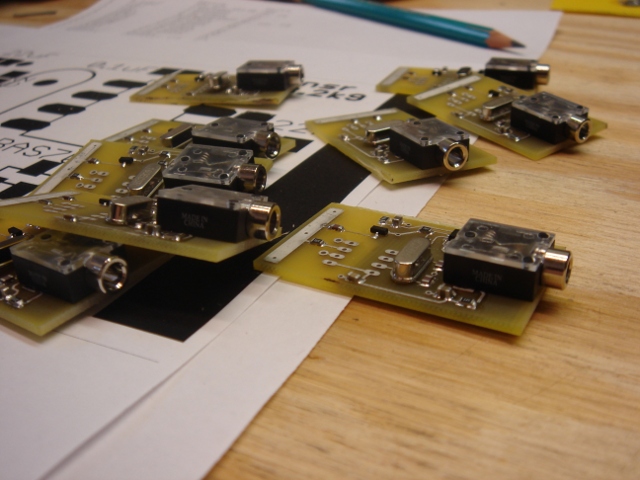

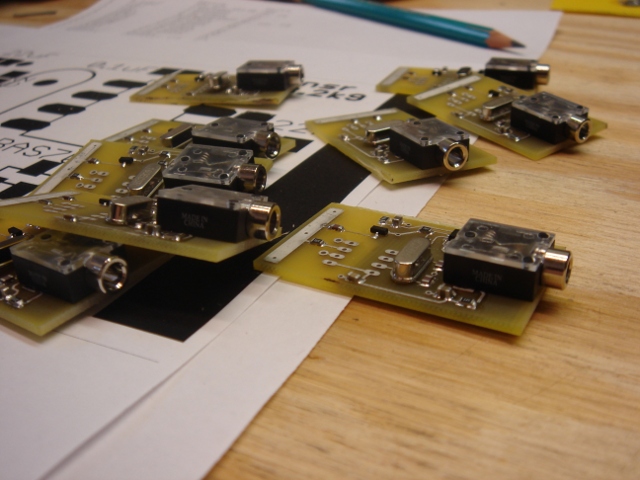

The touchsensors were actually fun to make. They’re an AVR which generates a crystal derived square wave (laziness on my part, and tunability. The generator could have been a logic gate or any crystal clock circuit really, although the programmable chip provided fudge room which I didn’t [and hopefully won’t] need) and drives it through a resistor to whatever gnarly sensor plate you have, and then filters and rectifies what’s left. They use hand capacitance to form a variable RC filter; the output of this device is a voltage which is inversely proportional to the capacitance at the sensing node. Not perfect, but pretty good. These sensors also use 1/8″ cables to carry power, ground, and signal, cause 1/8″ cables are cheap and promised to make wiring the beast a lot easier.

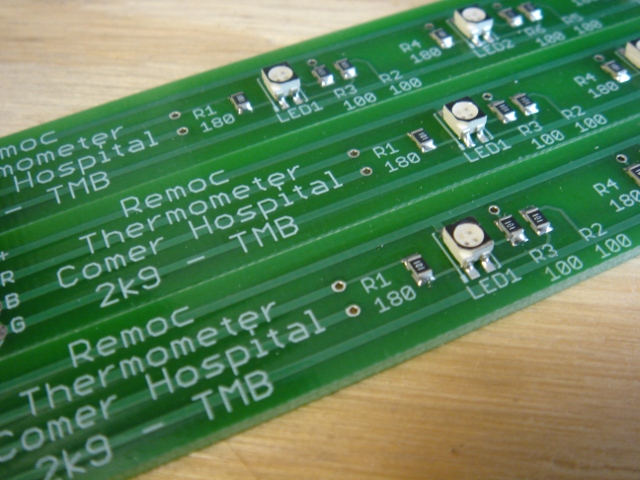

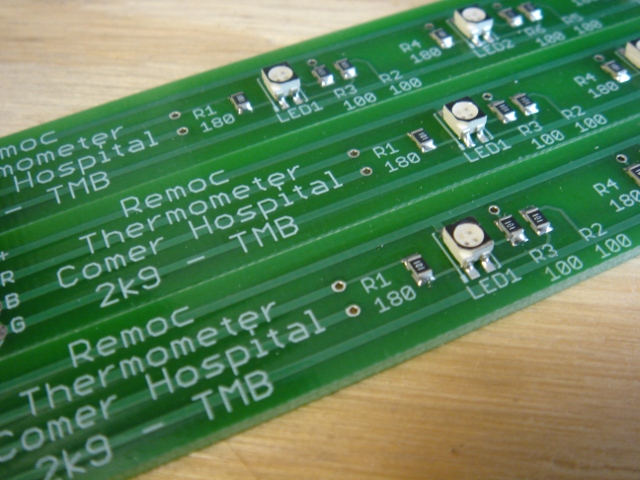

The thermometer. Some SMT LEDs on a stick. Yaaaawn.

All this stuff got packed up to schelp to Chicago.